The art of blacksmithing.

2 comments

The art of blacksmithing.

Grate ready to install

Sometimes I have to do or repair things the old-fashioned way, this time I had to make an iron fence with two wings, I have several tools that are necessary such as a welder, mask, electrodes, presses, hammer, wire brush among other things, which are necessary to carry out said work.

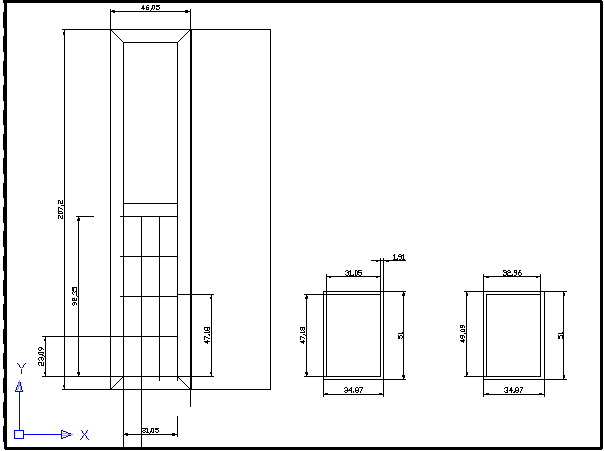

Sketch in CAD program

The model had to have certain characteristics because there were already other adjacent bars and it should keep the style so as not to look like a circus, the model in general is very simple, but there were some curls that it had to replicate.

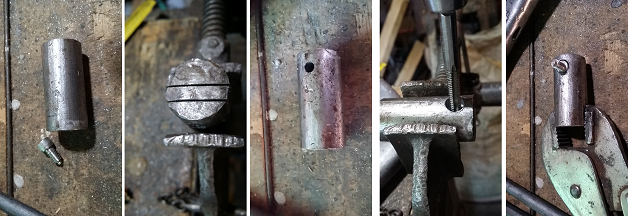

Manufacture of the tool.

Once the bar to be used in the fence has been sectioned, all that remains is to make a cut in the middle of approximately 12 cm long to form the curl. I hold it by a hold and use the tool with the help of a palanquin, the results were satisfactory because the curls were made without any inconvenience.

Curl creation

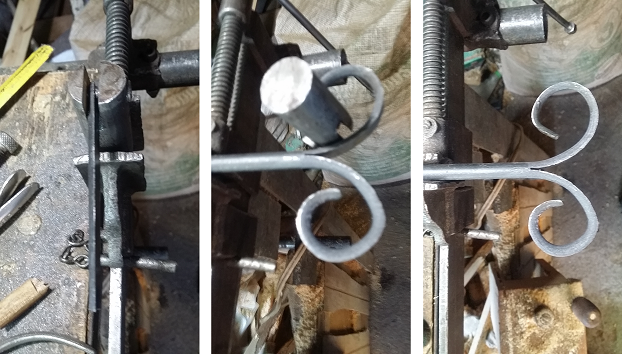

Once the curls were done, which was the most complicated part, it was finishing cutting the pieces of the 2 x 1 1/2 polished tube to assemble the grate, they were assembled taking into account their alignment at 90 degrees or square, the pieces were welded and the welders were finished off.

Upper and lower part of the bars.

Finally, the hinges on the respective wings were welded, I show you the result, the weld bead that looks like small coins together is observed in detail, this denotes a good weld. Additionally, knockers were placed to dock the doors.

Hinge

Comments